Efficient ink jet filtration makes all the difference

Creating the optimal digital image with ink jet printing is accomplished with the proper degassing of inks at the point of use and bulk ink filtration. Degassing and filtration of ink jet inks are critical to overcoming typical image quality and printhead performance challenges. For example:

- Eliminating large particulates, gel, contaminants, and agglomerated particles from inks

- Improve printer reliability and ink quality by separation of pigment salts, excess polymers, and surfactants

- Removing oversized insoluble dye particles that cause nozzle plugging, resulting in poor print quality and printer downtime.

- Removing entrapped gases and bubbles to ensure optimum printer performance

Efficient, industry-proven filtration and separation solutions

- As a filtration-intensive application, ink jet requires properly filtered ink to ensure the highest quality output and increased running periods, helping to reduce costs from production downtime and wasted ink and media.

- Our filtration and separation technologies cover the whole spectrum of printing-related filtration, whether it's onboard printer filtration, ink formulation, or ink degas. With our experienced technical support team, you can rely on specialist support to provide an optimized filter scheme that helps to reduce the overall cost of ownership.

To learn more about our solutions contact us on the form provided.

For more information on improving the efficiency of your processes, contact our team of filtration experts.

Ink degas

Ink formulation filtration

On Board Printer filtration

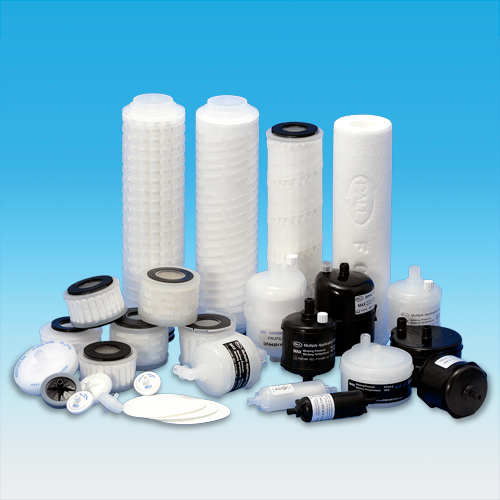

GRAPHIC ARTS Products

For more information about our range of products, explore our product catalog.