Renewable Fuel Production: The Role of Filtration

Bio-Based Feedstock Filtration: The New Frontier in Contamination Control

Renewable Fuel producers face new challenges with the wide range of bio-based feedstock processing available, all with varying types and levels of contamination. As producers look to ramp up capacities for renewable diesel and sustainable aviation fuel (SAF) the standard methods for protecting equipment and processes need to be re-evaluated to account for a new set of challenges that require advanced bio-feedstock filtration and robust contamination control of biofuels.

Why Filtration for Bio-Based Feedstock Processing is Critical

Unlike conventional crude oil, bio-feedstocks vary significantly in composition and quality. They often contain a wide range of contaminants that can degrade performance, damage equipment, and disrupt operations if not properly filtered.

Key Filtration Challenges in Biofuel Production

- Contamination types vary considerably from conventional crude feedstocks

- There is a wide range of contamination levels

- Variability of contamination size distribution

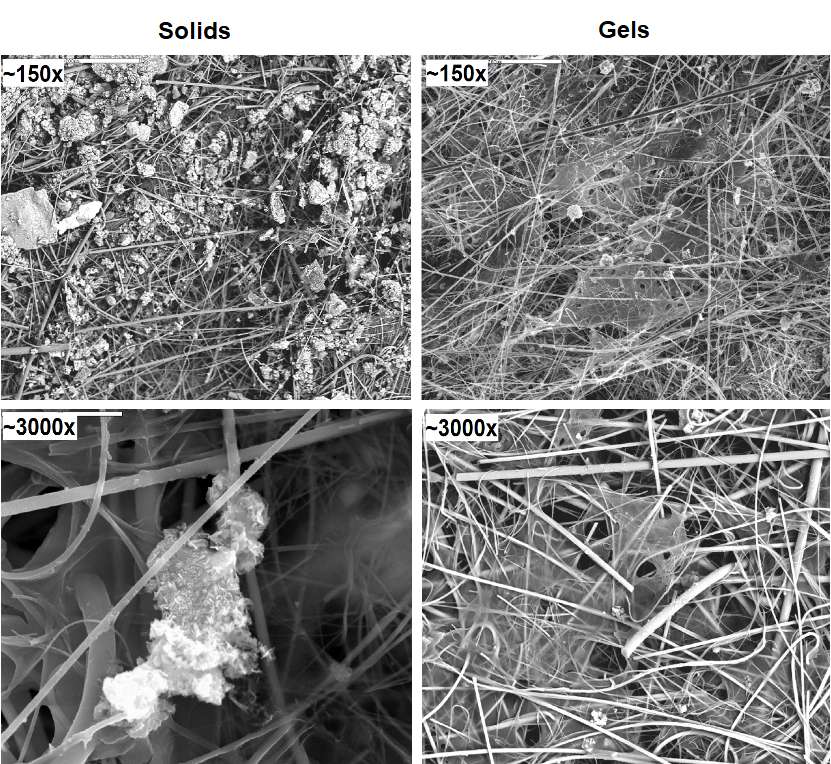

- Gel-like particulates are present

Even after biofuel pretreatment filtration, bio-based feedstocks can accumulate and introduce new contaminants during transport and storage. These include particulates and gel-like impurities, which can reduce filtration efficiency, shorten filter life, and cause equipment damage and process disruptions.

Additionally, the high oxygen content in bio-feedstocks converts to CO, CO2, and H2O during hydroprocessing. The volume of these byproducts varies by feedstock type, impacting refinery operations, catalyst protection, and moisture control.

Effective filtration for hydroprocessing units is essential to maintain operational efficiency and protect critical assets.

Key Filtration Points in Renewable Fuel Production

To ensure process reliability and product quality, filtration is essential at every stage of renewable fuel production:

- Feed Conditioning (Pre-Treatment): Removes particulates and gels to prevent fouling in heat exchangers and reactors.

- Burner Protection: Prevents fouling in fuel gas burners, reducing maintenance needs.

- Hydrogen Make-Up Filtration: Eliminates liquids from H₂ streams to protect catalyst beds.

- Recycle Gas Compressor Protection: Stops outages caused by hydrocarbon or sour water contamination.

- Amine Absorber Filtration: Reduces foaming and operational issues in the amine unit.

- Sour Water De-Oiling: Enhances product recovery and protects the sour water stripper.

- Product De-Watering & Filtration: Removes moisture and particulates before downstream processing.

- Hydrogen Unit Protection: Extends membrane and adsorbent life by preventing liquid ingestion.

- Final Product Filtration: Ensures compliance with cleanliness specs for solids and water content.

Benefits of using high-performance renewable fuel filtration solutions

To meet the demands of bio-based feedstock processing, producers must invest in high-efficiency bio-feedstock filtration systems tailored for renewable fuel production. These systems provide:

- Superior removal of particulates and gel-like contaminants

- Extended catalyst and equipment life

- Improved process stability and uptime

- Optimized hydrogen usage

- Lower total cost of ownership

Partner with Us for Advanced Biofuel Filtration

Our advanced filtration solutions for bio-based feedstocks are engineered to meet the unique demands of renewable diesel and SAF production. Whether you're scaling up or optimizing existing operations, we provide custom biofuel pretreatment filtration strategies and expert support for biofeedstock filtration. Our product range is designed to address the specific operational and environmental challenges faced by different sectors, helping companies meet applicable regulatory requirements in the regions where they operate.

Speak to one of our experts today to learn how we can help you protect your process and maximize performance.